Resistance projection welding, or RPW, is a form of resistance welding where the electricity, force, and time are concentrated on raised segments (or projections) to join items together. This process has the benefit of forcing the welds to occur in very specific and tiny locations, and minimizing the dissipation of heat to the rest of the metal sheets.

Resistance projection welding can be found in the automotive industry, where screw-fastener parts such as nuts and studs (see above) are joined to metal sheet components. It is also found in cross wire and bar welding, or in day to day products such as shopping carts. As with resistance spot welding, the difficulties in welding aluminum, high strength steels and coated steels has encouraged Huys to look for simple solutions. Some of our answers to these challenges include ceramic pins, modular weld heads, SORPAS® weld simulations, and upside-down nut detecting electrodes.

Applications of Resistance Projection Welding Services

As a leading resistance projection welding company in Canada, Huys offers RPW services across various industries. Automotive manufacturers use resistance projection welding services to secure components like nuts and studs to metal sheets. This process also plays a significant role in manufacturing products we see daily, like shopping carts, wire grills, and parts requiring cross-wire welding. The exact placement and low-heat advantages of RPW make it ideal for these applications, delivering strong, efficient welds.

Huys’ Advanced Solutions in Resistance Projection Welding

Huys focuses on innovation to overcome challenges in resistance projection welding, particularly with complex materials like aluminum, high-strength steels, and coated metals. As a resistance projection welding company, we use solutions such as:

- Ceramic Pins: For precise, wear-resistant placement during welds.

- Modular Weld Heads: Designed for flexibility and adaptability across different welding setups.

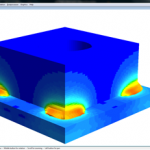

- SORPAS® Weld Simulations: To optimize weld quality and reduce trial and error.

- Upside-Down Nut Detecting Electrodes: Ensuring accurate and reliable welding in all orientations.

Why Choose Huys for Your Resistance Projection Welding Services?

Huys is recognized for high-quality resistance projection welding services that meet the rigorous demands of the automotive and manufacturing industries. Based in Ontario, Canada, we provide reliable solutions tailored to the unique needs of each client. Our experience and specialized technology make us the go-to resistance projection welding company for businesses seeking the best RPW solutions in Canada and beyond.

For more details on our resistance projection welding services, explore our full offerings.

Electrode Holders Barrels and Bases

Locating Weld Pins & Sleeves

Modular Weld Heads

Projection Grounding Block Electrodes

Resistance Welding Alloys

Resistance Welding Maintenance Tools

Shanks and Adaptors

Shunts and Cables

Spot Welding Electrodes

Welding Accessories

Harms & Wende Weld Controllers

HWH Service and Repair

SORPAS® FEA Weld Simulation