Patent Numbers: US 10,882,196 B2 / CA 2995658, US 10,829,856 B2 / CA 2712119, US 10,391,579 B2 / CA 2990246, US 10,391,574 B2 / CA 2905609, CA 3070994, CA 2874742

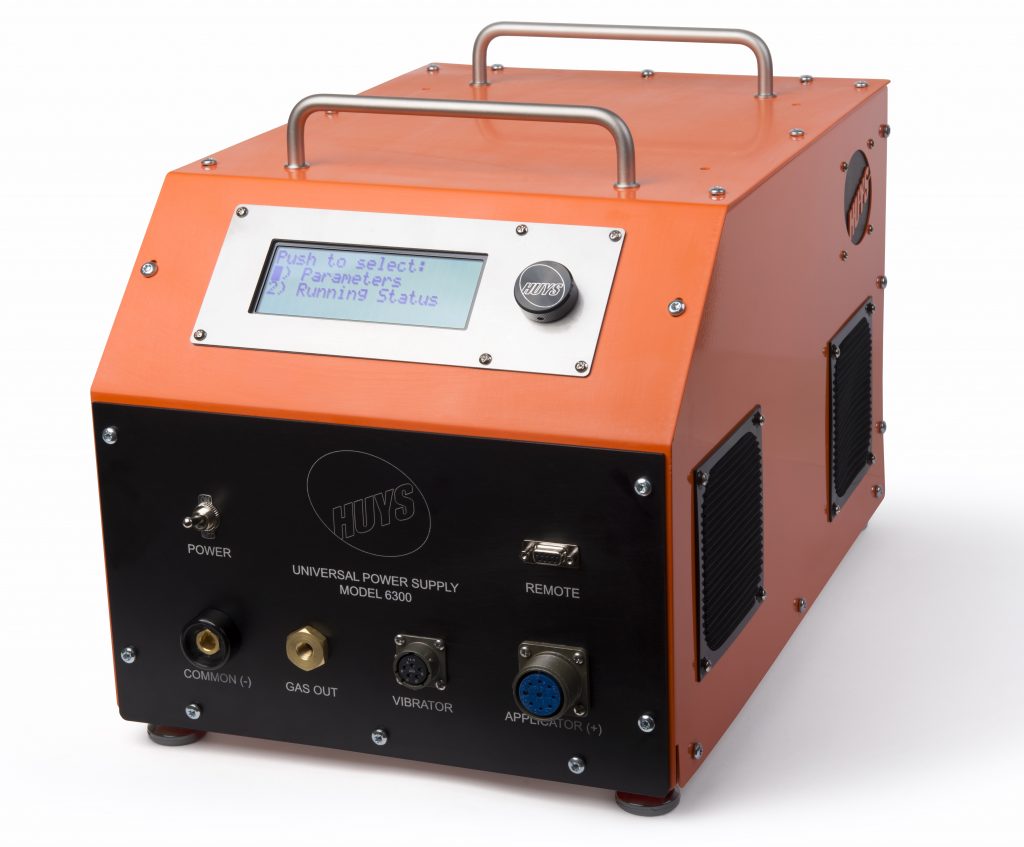

Huys designs, manufactures, sells, and supports its own electrospark deposition equipment (Low Energy Welding equipment). Should you wish to bring our LEW technology in-house, we have several standard power supply models to choose from that can be adapted to your needs.

| Model Name | Universal Power Supply | High Capacitance Power Supply | Coating Machine |

| Model Number | # 6300 | # 6310 | # 6320 |

| Input | 110-120 VAC / 220-240 VAC: Single Phase 50/60Hz | ||

| Capacity (KVA) | 1.2 | 1.2 | 1.44 |

| Dimensions (WxDxH) (inches) | 13 X 14 X 20 | ||

| Weight (lbs) | 65 | 65 | 56 |

| Output Voltage (VDC) | 140 | 80 | 34 |

| Maximum Capacitance (μF) | 310 | 1150 | 2000 |

| Maximum Pulse Energy (J) | 3.038 | 3.68 | 1.156 |

| Frequency Range | 10-500 | 10-500 | 50/60 |

Applicators

The other essential components of our LEW equipment are our applicators, which come in 3 main styles. These can be used with any of the above power supplies, and have key accessories/spare parts included. For demanding applications we can offer chillers and our water-cooled applicators.

Our engineers will help determine which applicator(s) would be best for your application. All applicators fit electrodes up to a 0.250” diameter.

For particularly unique or difficult applications, we have created a series of custom applicators.

If you would like more information, or to speak with our engineers, please reach out to us at sales@huysindustries.com or via our form.