Huys has the technical knowledge, experience, and support team to assist with virtually any material and substrate. Examples include:

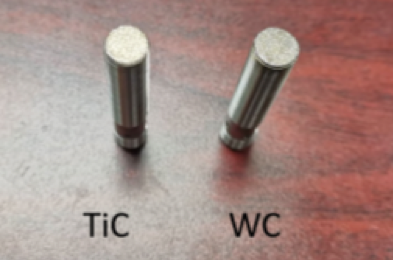

- Tungsten Carbide

- Titanium Carbide

- Nickel super alloys (MAR, IN718, HASTELLOY)

- Refractory metals

- Aluminum alloys

- Magnesium alloys

- Cobalt alloys (stellite)

- Titanium alloys

- Tantalum alloys

- Molybdenum alloys

This list below is a sampling of some of the projects we have worked on:

Aerospace

- To repair components that:

- Have Low Weldability

- Are Heat Treated

- Are Heat Sensitive

- Are High Value

- Are Thin Walled

- Examples: Turbine blades, engine cowlings

Industrial

- Machining

- Collets, jaws, clamping fingers, etc…

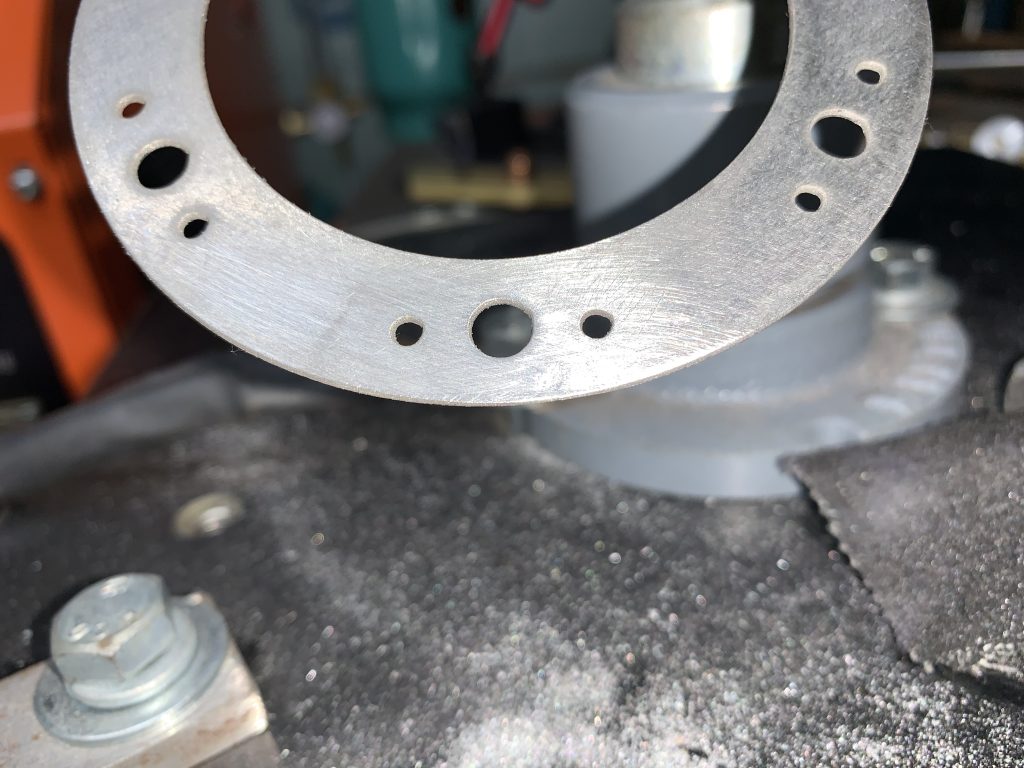

- Cutting Blades

- Primary Metals Industry

- Drums, spools, and mandrels for steel or aluminum manufacturing facilities

- Forming Press

- Die repair caused by high speed molten materials

- Cracks form due to repeated heating and cooling cycles

- Die repair caused by high speed molten materials

- Robot grippers to reduce slippage

- Custom coatings for tooling, equipment, or parts repair

Welding

- Resistance Welding electrodes

- Tooling

- MIG/TIG welding consumables

Electronics

- Repair and enhancement of conductive elements

- Resurfacing terminals with silver for high voltage applications

Consumer

- Repair of small surface damage

- Coating of cutting edges to maintain sharpness

- Ex: Axes, knives, chainsaws, lawn mower blades